Product Description

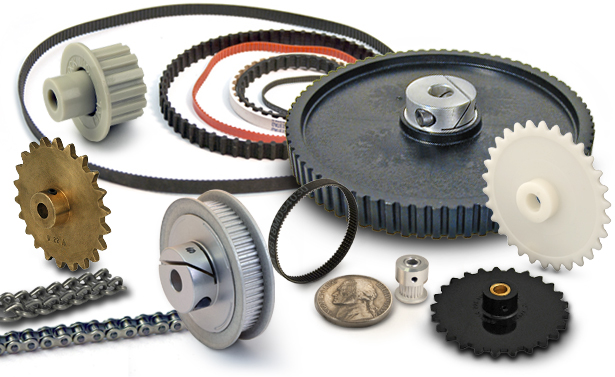

Taper Lock Pulley Bushes Belt Metal Bore Sprocket CHINAMFG Transmission Machine Parts Manufacture Best Sale Durable European Standard Durable Pulleys

V-Belt pulleys for taper bushes

Product Description

Pulleys belonging to wheel hub components are generally large in size, and their manufacturing processes are mainly casting and forging. Generally, the design with large size is cast iron (good casting performance), and cast steel is rarely used (poor casting performance); Generally, the smaller size can be designed as forgings and the material is steel. Belt pulley is mainly used for long-distance power transmission, such as the output of small diesel engines, agricultural vehicles, tractors, automobiles, mining machinery, mechanical processing equipment, textile machinery, packaging machinery, lathes, forging machines, power transmission of some small horsepower motorcycles, power transmission of agricultural machinery, air compressors, reducers, reducers, generators, cotton ginners, etc.

V-Belt Pulley:

The specifications of V-belts are divided by the dimensions of back width (top width) and height (thickness). According to different dimensions of back width (top width) and height (thickness), V-belts of different standards have different models. The pitch width, top width and height of V-belts of each model are different, so the pulley must also make various groove types according to the shape of V-belts; These different groove types determine various types of pulley.

| American Standard | |

AK/AKH BK/BKH TA/TB/TC Series Sheaves |

B/C/D Series Sheaves |

Poly-V Sheaves |

Variable Speed Sheaves |

| 3V/5V/8V sheaves | Bushings Split Taper Bushings/QD Bushings/TB Bushings |

European standard (SPA CHINAMFG SPC SPZ) |

|

Belt Pulleys for Taper Bushings |

V belt pulley with CHINAMFG hub |

Adjustable Speed V Belt Pulleys |

Flat Belt Pulleys For Taper Bushes |

In order to keep pace with changing trends of the industry, we are offering a quality assured assortment of CI Taper Lock Pulley. These products are manufactured with advanced technology and equipment to assure the production of faultless products. These products are extremely appreciated for their durability, reliability, corrosion resistant, abrasion resistant, and long service life.

Our competency lies in offering our clients an excellent quality range of Taper Lock Pulley And Bush. The provided coupling is carefully designed and manufactured by our adept professionals in tandem with specified globally accepted norms. This coupling is highly-demanded in numerous engineering industries owing to its striking features. In order to meet our client”s diverse demands, the provided coupling is available in various technical specifications. Moreover, we provide this coupling to our valued clients at pocket-friendly prices.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How are sprocket pulleys customized for specific applications and load requirements?

Sprocket pulleys can be customized to meet the specific requirements of different applications and load conditions. Here’s an explanation of how customization is achieved:

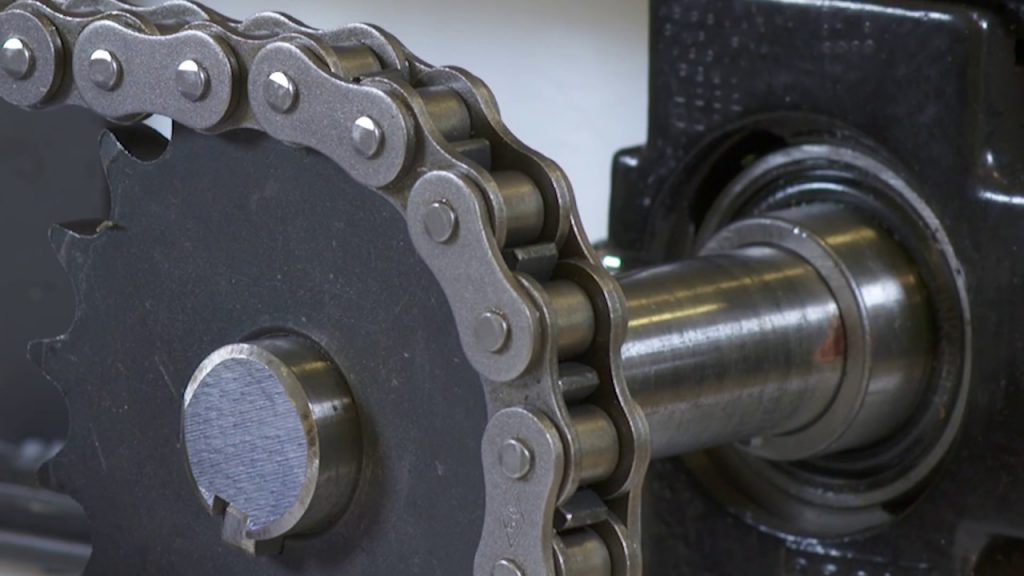

1. Size and Diameter: Sprocket pulleys are available in various sizes and diameters to accommodate different application requirements. The selection of the appropriate size and diameter depends on factors such as the available space, desired speed ratio, and torque transmission capabilities. Larger pulleys are typically used for applications that require higher torque transmission, while smaller pulleys are suitable for applications with limited space or lower load requirements.

2. Number of Teeth: The number of teeth on a sprocket pulley can be customized based on the desired speed ratio and load distribution. Pulleys with more teeth provide finer speed adjustments and distribute the load across a larger number of contact points, reducing wear and increasing load capacity. Conversely, pulleys with fewer teeth offer a coarser speed ratio but may be suitable for applications with limited space or specific torque requirements.

3. Material Selection: The choice of material for sprocket pulleys depends on factors such as the application environment, load requirements, and desired durability. Common materials used for sprocket pulleys include steel, cast iron, aluminum, and plastics. Steel and cast iron pulleys are known for their strength and durability, making them suitable for heavy-duty applications. Aluminum pulleys are lightweight and corrosion-resistant, often used in applications where weight reduction is important. Plastic pulleys are lightweight, economical, and can provide quieter operation.

4. Tooth Profile: The tooth profile of sprocket pulleys can be customized to match the corresponding chain type. Different chain types, such as ANSI, ISO, or specialty chains, have specific tooth profiles that ensure proper engagement and smooth operation. Customizing the tooth profile allows for compatibility and optimized performance between the sprocket pulley and the chain.

5. Coating and Surface Treatment: Sprocket pulleys can be coated or surface-treated to enhance their performance in specific applications. Coatings such as zinc plating, black oxide, or corrosion-resistant coatings can improve the pulley’s resistance to wear, rust, and environmental conditions. Surface treatments like heat treatment or induction hardening can increase the hardness and wear resistance of the pulley teeth, prolonging their lifespan in demanding applications.

6. Special Features: Depending on the application requirements, sprocket pulleys can be customized with special features. These features may include timing marks, keyways, set screws, hubs, or flanges to facilitate precise positioning, mounting, or connection with other components in the system.

7. Engineering Support: Customization of sprocket pulleys often involves engineering support to ensure that the pulley design meets the specific application and load requirements. Manufacturers or suppliers can provide assistance in selecting the appropriate pulley specifications, considering factors such as load capacity, speed, torque, and environmental conditions.

By offering customization options in terms of size, diameter, number of teeth, material selection, tooth profile, coating, surface treatment, and special features, sprocket pulleys can be tailored to meet the unique demands of various applications and load requirements.

What is the significance of proper lubrication and maintenance in sprocket pulley systems?

Proper lubrication and maintenance play a crucial role in ensuring the optimal performance, longevity, and safety of sprocket pulley systems. Here are several key reasons why proper lubrication and maintenance are significant:

1. Reduced Friction and Wear: Lubrication helps reduce friction between the sprocket pulleys and the chain, minimizing wear on the components. By providing a lubricating film between the moving parts, proper lubrication prevents metal-to-metal contact and the resulting wear, which can lead to premature failure. It promotes smooth and efficient operation, preserving the integrity and lifespan of the sprocket pulley system.

2. Prevention of Corrosion and Rust: Lubricants act as a protective barrier, preventing corrosion and rust formation on the sprocket pulleys and the chain. Exposure to moisture, contaminants, or harsh environments can lead to corrosion, compromising the functionality and structural integrity of the components. Proper lubrication helps create a protective layer, inhibiting the detrimental effects of corrosion and extending the service life of the sprocket pulley system.

3. Optimal Power Transfer: Adequate lubrication ensures optimal power transfer within the sprocket pulley system. The lubricant helps reduce energy losses due to friction, allowing efficient power transmission from the driving source to the driven components. This results in improved overall system performance, reduced energy consumption, and enhanced productivity.

4. Noise Reduction: Proper lubrication contributes to noise reduction in sprocket pulley systems. By minimizing friction and damping vibrations, lubricants help reduce the noise generated during the operation of the chain drive system. This is particularly important in applications where noise control is essential, such as in precision machinery, robotics, or equipment operating in noise-sensitive environments.

5. Maintenance of Tension and Alignment: Regular maintenance, including lubrication, allows for the proper maintenance of tension and alignment in the sprocket pulley system. Over time, the chain may stretch or the sprocket pulleys may experience misalignment, affecting the system’s performance and reliability. By incorporating lubrication as part of the maintenance routine, these issues can be addressed, ensuring consistent tension and alignment for optimal functioning.

6. Identification of Wear or Damage: During maintenance activities, such as lubrication, close inspection of the sprocket pulley system can help identify signs of wear, damage, or misalignment. Regular visual inspections and lubrication intervals provide opportunities to detect and address any issues before they result in major failures or breakdowns. Timely maintenance and repair can prevent costly downtime and extend the service life of the sprocket pulley system.

7. Safety Enhancement: Proper lubrication and maintenance contribute to a safer working environment. Well-maintained sprocket pulley systems are less prone to unexpected failures, minimizing the risk of accidents, injuries, or damage to equipment and surrounding infrastructure. Regular maintenance practices, including lubrication, ensure that the sprocket pulley system operates reliably and safely.

In summary, proper lubrication and maintenance are essential for reducing friction and wear, preventing corrosion, optimizing power transfer, reducing noise, maintaining tension and alignment, identifying wear or damage, and enhancing safety in sprocket pulley systems. Adhering to manufacturer recommendations and implementing a regular maintenance program is vital to maximize the performance and durability of the system.

What role do sprocket pulleys play in maintaining tension and alignment in chain-driven systems?

Sprocket pulleys play a crucial role in maintaining tension and alignment in chain-driven systems. Here’s an explanation of their role:

1. Tension Control: Sprocket pulleys help in maintaining proper tension in the chain. The teeth on the pulley engage with the chain links, creating a positive connection. By adjusting the position of the sprocket pulleys or using tensioning devices, the tension in the chain can be regulated. Proper tension is vital for smooth and efficient power transmission, as excessive slack or tightness can lead to performance issues and premature wear of the chain and sprocket pulleys.

2. Alignment Maintenance: Sprocket pulleys assist in maintaining proper alignment of the chain. The teeth of the pulley guide the chain, keeping it in line and preventing it from deviating or slipping off the pulley. The accurately machined tooth profile and the precise spacing between the teeth ensure that the chain remains aligned with the pulley throughout its operation. This alignment is essential for reliable and efficient power transmission.

3. Tensioner and Guide: Some chain-driven systems incorporate additional components such as tensioners and guides alongside the sprocket pulleys. Tensioners help to maintain tension in the chain by applying a controlled force to compensate for chain elongation or thermal expansion. Guides keep the chain properly aligned, especially in applications with complex paths or multiple sprocket pulleys. These additional components work in conjunction with the sprocket pulleys to ensure optimal tension and alignment throughout the chain-driven system.

4. Reduction of Vibrations: Proper tension and alignment maintained by the sprocket pulleys help reduce vibrations in chain-driven systems. Vibrations can occur when the chain experiences excessive slack or misalignment, leading to noise, increased wear, and reduced efficiency. The positive engagement between the sprocket pulleys and the chain, along with the consistent tension and alignment, minimizes vibrations, ensuring smoother and quieter operation.

5. Enhanced System Performance: By maintaining tension and alignment, sprocket pulleys contribute to the overall performance of chain-driven systems. Proper tension ensures efficient power transfer, while accurate alignment reduces wear and extends the lifespan of the chain and sprocket pulleys. This results in improved system reliability, reduced downtime, and enhanced productivity in various applications.

6. Maintenance Considerations: Regular inspection and maintenance of sprocket pulleys and the chain are essential to ensure optimal tension, alignment, and performance. Lubrication of the chain and periodic inspection of the sprocket pulleys help minimize friction, wear, and noise, ensuring smooth operation and preventing premature failure.

In summary, sprocket pulleys play a vital role in maintaining tension and alignment in chain-driven systems. Their ability to control tension, guide the chain, reduce vibrations, and enhance system performance makes them indispensable components in applications such as machinery, conveyors, power transmission systems, and more.

editor by CX

2024-05-17