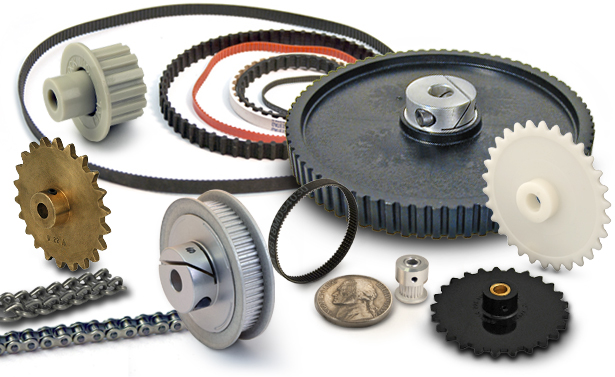

Product Description

ZhenJiang CHINAMFG Machinery Co., Ltd., an export oriented Chinese-American joint-venture, is established in 1999, and is located in ZhenJiang, ZheJiang Province, Which is included in Yangtse rive CHINAMFG developing zone in East China. As a close neighbor of ZheJiang , an international metropolis of financial, trading and commercial center, its convenience in water and land transportation.

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with the best quality at the reasonable price.

| Item No. |

Descriptions | Main Mat’l | Package pcs |

G.W. kg |

||

| 12500 | Φ40 sprocket pulley |

|

steel sheave, steel strap |

/pallet | |||

| 50 | /master carton |

||||||

| Φ40 | /bag |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | C.V. Joints |

|---|---|

| Material: | Steel |

| Certification: | ISO, DIN, CE, ASTM |

| Standard: | Standard |

| Condition: | New |

| Size: | 40 |

| Customization: |

Available

| Customized Request |

|---|

Are there different types of sprocket pulleys, and how do they vary in industrial use?

Yes, there are different types of sprocket pulleys, each designed to suit specific industrial applications. Here’s an explanation of the various types and their variations:

1. Standard Sprocket Pulleys: Standard sprocket pulleys are the most common type and are widely used in industrial applications. They typically have a cylindrical shape with evenly spaced teeth and are available in various sizes and materials. Standard sprocket pulleys are used in a wide range of industries, including manufacturing, automotive, agriculture, and machinery.

2. Taper-Lock Sprocket Pulleys: Taper-lock sprocket pulleys have a unique design that allows for easy installation and removal. They feature a tapered bore with a corresponding sprocket hub that can be mounted on a shaft by tightening a set of screws. Taper-lock pulleys provide a secure and reliable connection, making them suitable for applications where frequent pulley changes or maintenance is required.

3. Split Sprocket Pulleys: Split sprocket pulleys are designed with a split hub or a two-piece construction that allows for easy installation or replacement without the need to disassemble the entire system. They are commonly used in applications where access to the shaft or the chain is limited, making maintenance or pulley changes more convenient.

4. Idler Sprocket Pulleys: Idler sprocket pulleys are used to guide or redirect the chain in a chain-driven system. They do not transmit power but help to maintain proper tension and alignment. Idler pulleys are often used in applications with complex paths, multiple sprocket pulleys, or long spans between driving and driven pulleys. They contribute to reducing chain vibration, enhancing system stability, and improving overall performance.

5. Specialty Sprocket Pulleys: Specialty sprocket pulleys are designed for specific applications or unique requirements. They may include custom tooth profiles, non-standard sizes, or specialized materials. Examples of specialty sprocket pulleys include those used in high-temperature environments, food-grade applications, or in industries such as mining, forestry, or marine where they need to withstand harsh conditions.

6. Timing Belt Pulleys: Although not technically sprocket pulleys, timing belt pulleys are worth mentioning as they serve a similar purpose in power transmission systems. Timing belt pulleys have grooves that match the teeth of timing belts, enabling precise motion control and synchronization. They are commonly used in applications that require accurate positioning, such as robotics, CNC machines, and printing presses.

Each type of sprocket pulley offers specific advantages and is selected based on factors such as the application requirements, load conditions, ease of installation, maintenance considerations, and the desired performance of the chain-driven system.

How do sprocket pulleys enhance the overall precision and control of mechanical operations?

Sprocket pulleys play a significant role in enhancing the overall precision and control of mechanical operations. Here are several ways in which they contribute to improved accuracy and control:

1. Precise Positioning: Sprocket pulleys, in conjunction with a chain drive system, enable precise positioning of components or equipment. By accurately engaging with the teeth of the chain, the sprocket pulleys allow for controlled movement and positioning of the driven components. This precision is crucial in applications where precise alignment or synchronization is required, such as robotics, assembly lines, or printing machinery.

2. Speed Control: Sprocket pulleys, combined with the appropriate chain drive ratio, provide precise speed control in mechanical operations. By selecting sprocket pulleys with different diameters or tooth counts, the rotational speed of the driven component can be adjusted relative to the driving source. This allows for fine-tuning the speed of machinery or systems, ensuring optimal performance and preventing issues related to excessive or insufficient speed.

3. Load Distribution: Sprocket pulleys help distribute loads evenly across the chain drive system, enhancing overall control. As the chain engages with the sprocket pulleys, the load is distributed among multiple teeth, reducing the stress on individual components. This load distribution minimizes the risk of premature wear, fatigue, and component failure, ensuring smoother and more reliable mechanical operations.

4. Motion Synchronization: Sprocket pulleys enable precise motion synchronization in mechanical operations. When multiple sprocket pulleys are used in a chain drive system, they can be strategically positioned to synchronize the movement of different components or equipment. This synchronization ensures coordinated motion, preventing issues such as misalignment, skewing, or timing errors. Examples include the synchronized movement of conveyor belts on assembly lines or the coordinated motion of robotic arms in industrial automation.

5. Reduced Backlash: Backlash refers to the play or clearance between mating components in a mechanical system. Sprocket pulleys, when properly designed and implemented, can help reduce backlash in chain drive systems. By maintaining a tight engagement with the chain, sprocket pulleys minimize the amount of play or backlash, resulting in improved precision and control. This is particularly important in applications that require accurate reversals, quick response times, or minimal positional errors.

6. Controlled Torque Transmission: Sprocket pulleys facilitate controlled torque transmission, allowing for precise power delivery in mechanical operations. The engagement between the sprocket pulleys and the chain enables the transfer of torque from the driving source to the driven component. This controlled torque transmission ensures smooth and consistent power delivery, reducing the risk of sudden jolts, jerks, or fluctuations in rotational motion. It is crucial in applications that demand accurate torque control, such as robotic manipulators, machine tools, or industrial presses.

Overall, sprocket pulleys enhance precision and control in mechanical operations by enabling precise positioning, speed control, load distribution, motion synchronization, reduced backlash, and controlled torque transmission. Their reliable and efficient operation contributes to improved accuracy, repeatability, and performance in a wide range of industrial applications.

What is a sprocket pulley, and how does it differ from traditional pulleys?

A sprocket pulley is a type of pulley that incorporates teeth or cogs, called sprockets, on its outer circumference. These teeth mesh with the links of a chain or a timing belt, allowing the sprocket pulley to transmit power or motion. Here’s a detailed explanation of what a sprocket pulley is and how it differs from traditional pulleys:

1. Design and Construction: Sprocket pulleys have a distinct design with teeth or cogs arranged around the outer rim. These teeth are specifically designed to engage with the links of a chain or a timing belt. In contrast, traditional pulleys typically have a smooth or grooved surface without any teeth.

2. Power Transmission: Sprocket pulleys are primarily used for power transmission in applications where the torque and speed need to be transferred accurately. The engagement between the sprocket pulley’s teeth and the chain or timing belt ensures a positive and reliable power transfer. Traditional pulleys, on the other hand, are commonly used for transmitting power through belts or ropes, relying on friction between the pulley surface and the belt.

3. Alignment and Tension: Sprocket pulleys require precise alignment to ensure smooth operation and prevent the chain or timing belt from derailing. Proper tensioning of the chain or timing belt is also crucial to maintain the engagement between the sprocket pulley’s teeth and the links. Traditional pulleys, while still requiring proper alignment and tension, do not have the same level of dependency on precise alignment and tensioning as sprocket pulleys.

4. Applications: Sprocket pulleys are commonly used in various applications that require accurate power transmission, such as bicycles, motorcycles, conveyors, industrial machinery, and automotive engines. They are particularly suitable for applications that involve high-speed or heavy-duty operations. Traditional pulleys, on the other hand, are used in a wide range of applications, including lifting systems, belt-driven machinery, and mechanical systems where precise power transmission is not a critical requirement.

5. Speed and Torque: Sprocket pulleys are designed to handle high speeds and transmit substantial torque efficiently. The teeth on the sprocket pulley ensure a positive engagement with the chain or timing belt, allowing for reliable power transmission even at high speeds. Traditional pulleys, although capable of transmitting power, may not be as efficient or suitable for high-speed or high-torque applications.

6. Customization and Variability: Sprocket pulleys offer a higher degree of customization and variability compared to traditional pulleys. They are available in various sizes, tooth profiles, and configurations to accommodate specific chain or timing belt requirements. Traditional pulleys, while offering some degree of customization, are generally limited to a few standard sizes and groove configurations.

7. Maintenance and Lubrication: Sprocket pulleys require periodic maintenance, including lubrication of the chain or timing belt and regular inspection of the teeth and links. Proper lubrication ensures smooth operation and extends the lifespan of both the sprocket pulley and the chain or timing belt. Traditional pulleys may also require maintenance, such as belt tension adjustment or pulley cleaning, but do not involve the same level of lubrication and inspection as sprocket pulleys.

In summary, a sprocket pulley is a specialized type of pulley that incorporates teeth or cogs on its outer circumference to engage with a chain or timing belt for power transmission. It differs from traditional pulleys in terms of design, power transmission mechanism, alignment and tension requirements, applications, speed and torque capabilities, customization options, and maintenance needs.

editor by CX

2024-05-08